RF BULLET 3000AQ

Rapidfire

zapytaj o produktTable working area – 1600x3150mm. Other dimensions on request.

The Y-axis drives – Precision planetary backlash-free gears. Usage of this kind of drive allows for perfect repeatability of production. It also limits the frequency of services related to regulation and calibration.

The Y-axis drives have been installed on both sides, and the motors position themselves independently of the set parameters, thus eliminating the formation of the diagonal bevel of the portal. They work even more precisely to get the maximum quality of the cut detail during plasma or gas cutting.

Triple homing system – This is the unique advantage of the software, which combines all available torch’s calibration technologies in one machine.

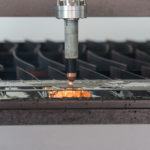

Water grate as a standard – It will reduce the costs associated with the purchase of filtration and its operation. It is always possible to install a sectional smoke extraction system depending on the entrepreneur’s needs.

Mechanical anti-collision torch holder – excellent protection of the Z axis and protection gains damage of portal components.

Torch with automatic electric-mechanical height control – precise positioning over the material being cut has been perfected. The curve of the cut surface is no longer an issue. The correct Torch height is an extremely important element of a proper high efficiency of cutting. Our solution will significantly reduce the consumption of consumables and increase the possibility of perforate the thickest materials.

MOBILE II control panel – For particularly demanding users. Reinforced resistant to mechanical damage, made very carefully with attention to details, such as: a slide-out keyboard cabinet or wheels with the possibility of blocking. Includes an Intel Pentium processor with SSD disc and Wi-Fi allows you to start cutting in 20 sec. All drawings readable on a large screen, and a double-layered glued glass which is protecting the screen is a more effective solution than a tempered glass.

Ball conveyors – for easy loading of material.

How do Rapid Fire technologies help in the operator’s daily work?

According to our idea of high quality, we took care of your production even more than others. While programming the latest version of the software, we also took into account the possibility of a failure and the speed of its removal. How do we implement it?

Remote factory reset – your machine connected to the network will allow remote diagnosis at a surprisingly fast time. We will diagnose the problem and tell you how to solve it. Moreover, if it turns out that the operator made a mistake, we can restore the system remotely to the factory settings without losing all data (regarding e.g. cutting, a particular detail, current work). They are stored in a safe place on the controllers.

Application of an anti-collision torch holder and the specificity of table control relies on the immediate transfer of information to the interface in a situation when something went wrong and the machine should be turn off to check it accordingly. The optional servo motors – will not only transfer information to the system, but will also stop the machine. The location of the torch operation before the failure is retained in our CONTROLLER and will be restored.

Place restoration of finished work after a breakdown – data and co-ordinates are stored in the main controller of the machine R2D2 CONTROLLERS.

Computer does not work, cutting data is lost – in the case of a computer failure, you will not lose all data. All you need to do is upload our program to a different PC and you will be able to continue your work with the parameters stored in the CONTROLLER.

Laser pointer – it precisely allows to indicate the place where the cutting on the surface of the sheet metal starts. This is a great convenience for operators.

Safe electronics – Table service is very simple thanks to a removable, isolated electronics panel located in the control panel.

OPTIONAL:

Modular structure – the table can be expanded with further modules up to the maximum dimensions of the working field 1600mm x 6150m.

Portal extension – possibility of installing/replacing for a longer portal in order to operate the torch outside the working surface of the table. This solution is used to cut pipes and profiles next to the table.

Transport pitchfork- enables transport with a forklift truck.

Plasma and gas burning – depending on the client’s needs, we are able to modify the table, so that can cut with a gas torch. All components together with the software are adapted for this purpose. The torch holder allows you to quickly change the plasma torch to gas torch and vice versa, as needed.

Accessory servo motors – during a failure, they stop the machine’s work without causing further errors during cutting.

Remote control adapter – operator will be able to control the work of the table with the remote control.

Traditional extractor – possible installation of a sectional fume extractor and filtering ventilation.

Remote diagnosis will speed up the service – PRO-Net technology allows a quick diagnosis via Wi-Fi (necessary access to the network in the workplace of the device).

Control:

System Rapid Fire „Enigma”.

ENIGMA consists of electronic components, drivers and software that allows you to achieve the best cutting results. Its unique and more user-friendly than standard cutting control systems.

More information can be found in the brochure, which we will send to your e-mail adress.

Check RF BULLET 3000AQ promo video!

Wyposażenie dodatkowe

(PL) Wskażnik laserowy

(PL) Ruszt wodny

(PL) Kontroler R2D2

(PL) Przekładnie planetarne

(PL) Atrakcyjna cena w stosunku do wysokiej jakości

(PL) Profesjonalne oprogramowanie

zapytaj o produkt

SKONTAKTUJ SIĘ Z NAMI

RapidFire

ul. Kaczeńcowa 2

51-180 Wrocław, Poland

tel:(PL) (+48) 669 120 008

email: OFFICE@RAPIDFIRE.PL

WYŚLIJ NAM WIADOMOŚĆ

Szukasz niestandardowych rozwiązań?

Skontaktuj się z nami. Razem znajdziemy rozwiązanie